A inductive proximity sensor can detect metal targets approaching the sensor, without physical contact with the target. Inductive Proximity Sensors are roughly classified into the following three types according to the operating principle: the high-frequency oscillation type using electromagnetic induction, the magnetic type using a magnet, and the capacitance type using the change in capacitance.

General sensor

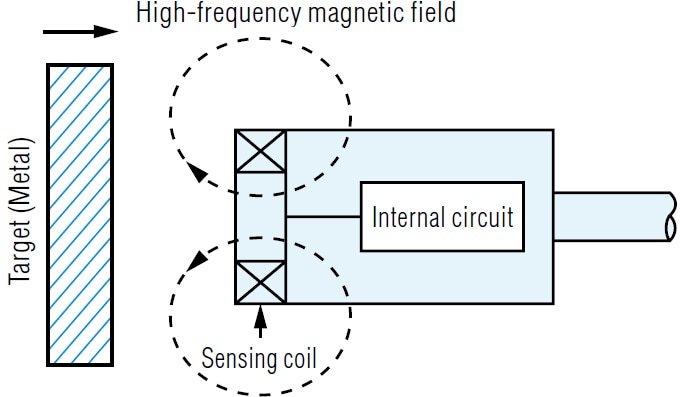

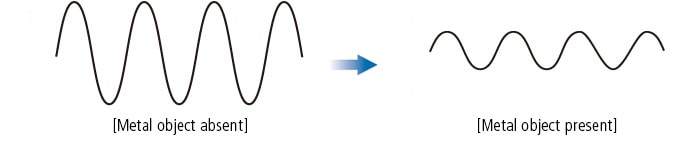

A high-frequency magnetic field is generated by coil L in the oscillation circuit. When a target approaches the magnetic field, an induction current (eddy current) flows in the target due to electromagnetic induction. As the target approaches the sensor, the induction current flow increases, which causes the load on the oscillation circuit to increase. Then, oscillation attenuates or stops. The sensor detects this change in the oscillation status with the amplitude detecting circuit, and outputs a detection signal.

Nonferrousmetal type

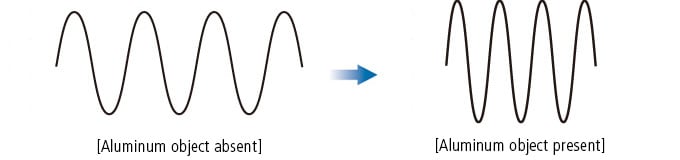

The nonferrous-metal type is included in the high-frequency oscillation type. The nonferrous-metal type incorporates an oscillation circuit in which energy loss caused by the induction current flowing in the target affects the change of the oscillation frequency. When a nonferrous-metal target such as aluminum or copper approaches the sensor, the oscillation frequency increases. On the other hand, when a ferrous-metal target such as iron approaches the sensor, the oscillation frequency decreases. When the oscillation frequency becomes higher than the reference frequency, the sensor outputs a detection signal.

Magnetic objects and non-magnetic objects Remember that magnetic objects are easily attracted by a magnet, whereas non-magnetic objects are not.

| Magnetism |  |

|---|---|

| Detecting distance of general-purpose model |  |

| Detecting distance of aluminum detection model |  |

| Typical metal | Iron – SUS304* – Aluminum/copper |